1. Upload STEP/STL Files

for sample geometry, multi-materials and region of interest

2. Set System Parameters

Enter turntable size, target magnification, detector and mechanical limits.

3. Choose Scan Mode

Field-of-view extensions, limited angle, helical scanning, geometric constraints

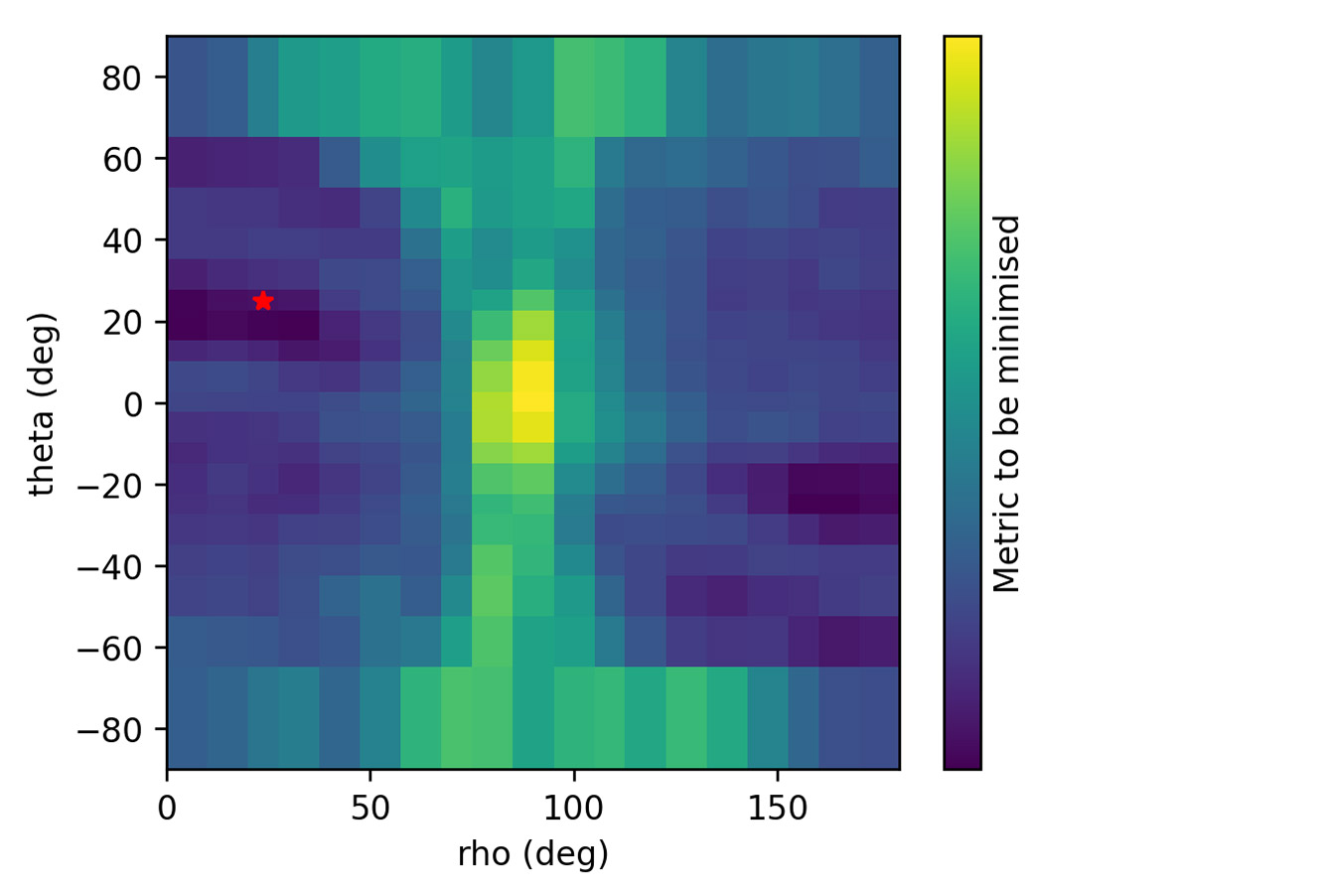

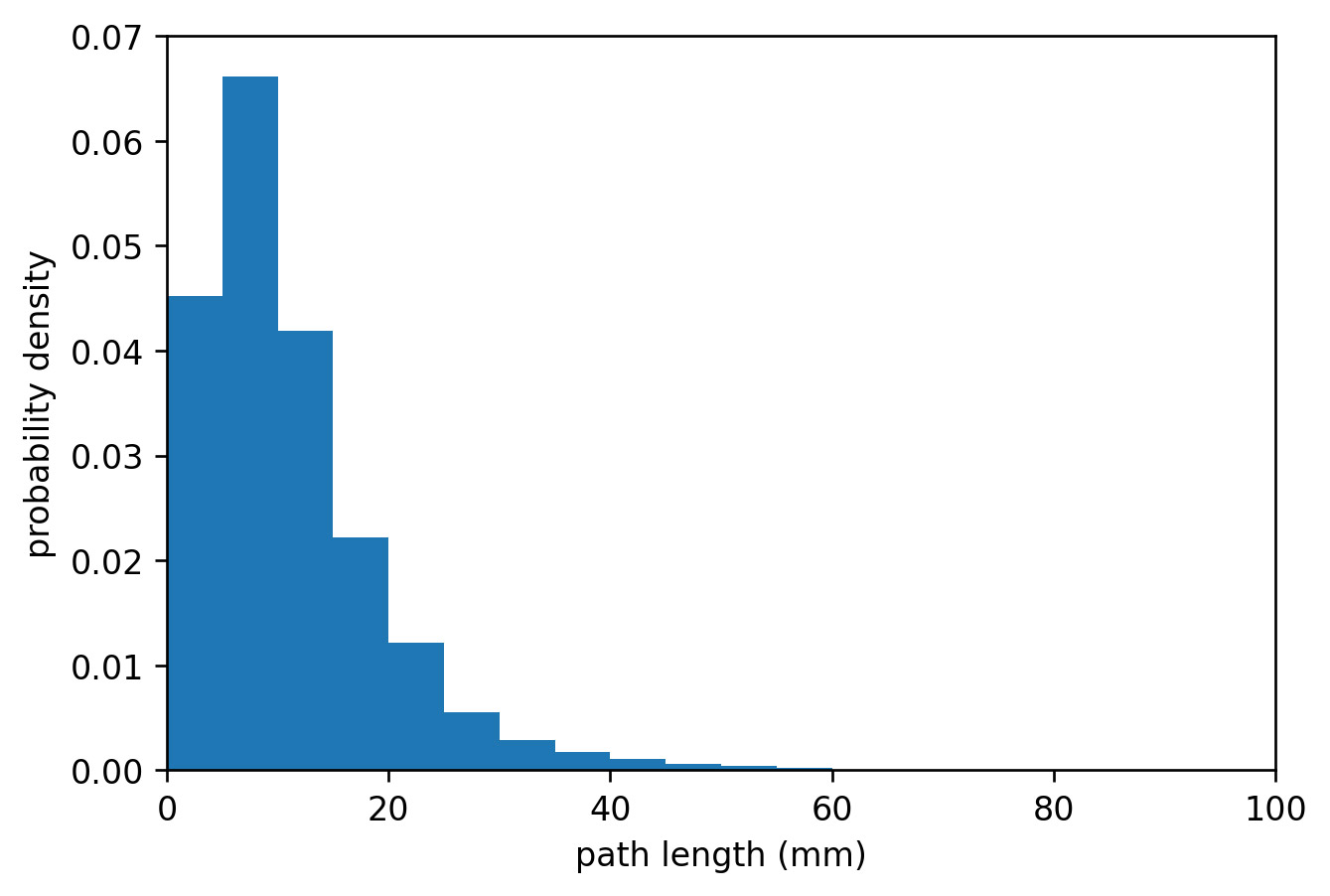

4. Compute Optimization

GPU accelerated simulation allows many possible configurations to be explored efficiently.

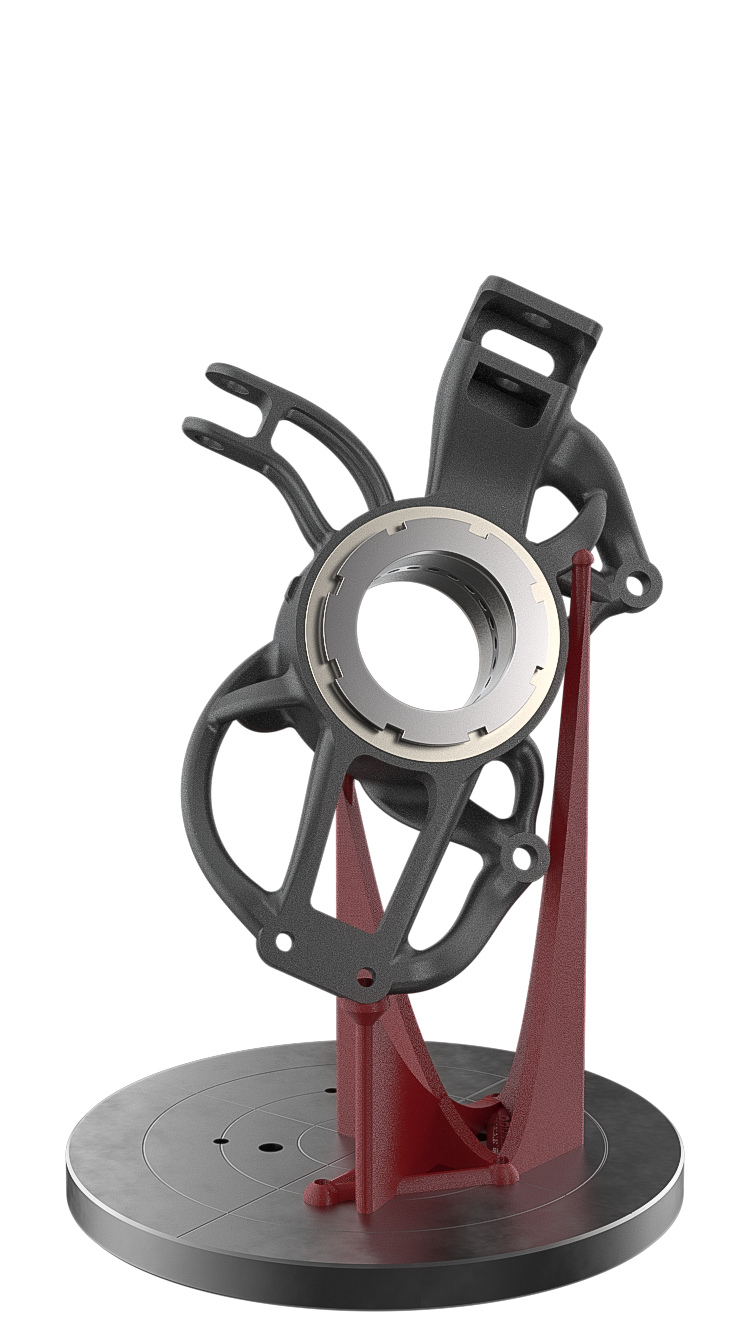

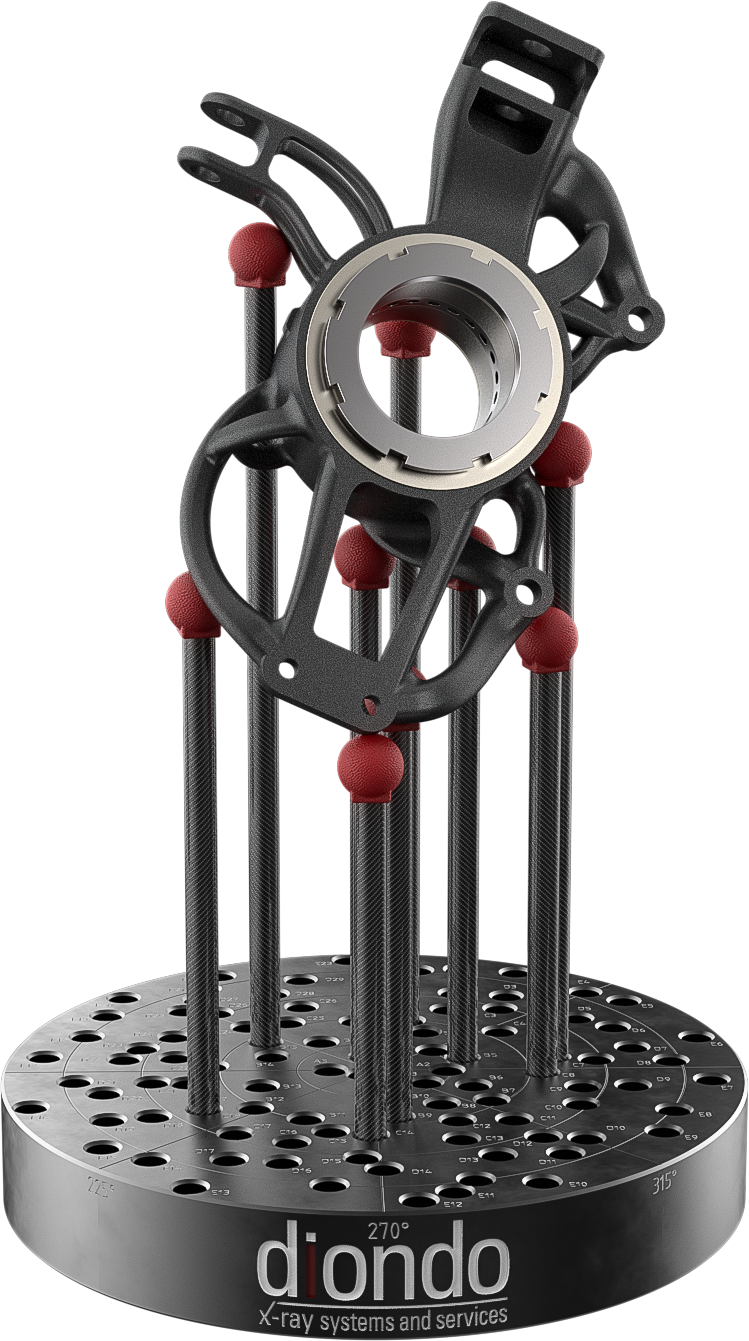

5. Export Fixture

3D-print geometry (FixPrint) or reconfigurable kit (FlexConfig).

6. Run your CT Scan

Repeatable, traceable setup — less trial-and-error.

From CAD to CT. Perfectly aligned.

From CAD to CT. Perfectly aligned.